VENEERING

A project begins as plans are examined in detail by a project manager and is budgeted by our estimating staff.

Our project manager will follow a job through from estimating to completion and billing. With an approved estimate, our draftsmen generate millwork drawings and a cut list (assisted by CAD/CAM systems that can translate drawings directly into CNC machine-code).

Every operation from sawing and laminating through joining, finishing and installation is accounted for. Shop drawings, together with finished veneer and solid samples, are then submitted for customer sign-off. Before the first cuts are ever made, any aspects of design requiring special attention are identified and resolved.

The key to success for each project is the selection and matching of materials.

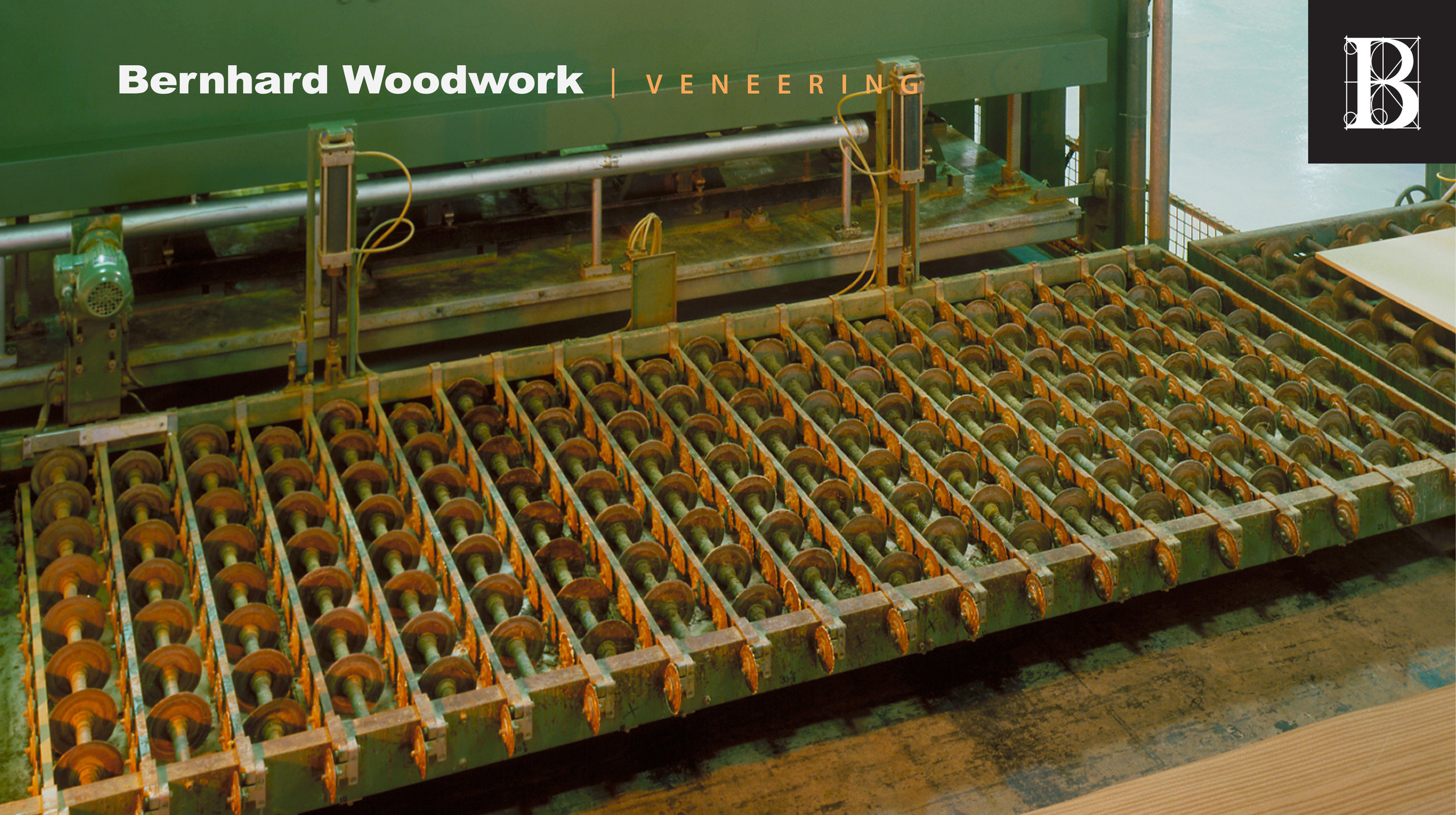

Integral to the process is veneer lay-up. Usually hand selected from a single fitch of wood, we lay-up veneer on our own veneer press custom built to Bernhard specifications. Producing out own veneer panels allows us to balance the grain, burl, texture and color of each panel to bring out the characteristic beauty of each wood species.

Our 64' x 157" Ott is one of the largest architectural woodwork veneer presses in the United States. Laying up our own veneer not only results in a more beautiful product, it also enables us to turn around your job faster.