ASSEMBLY

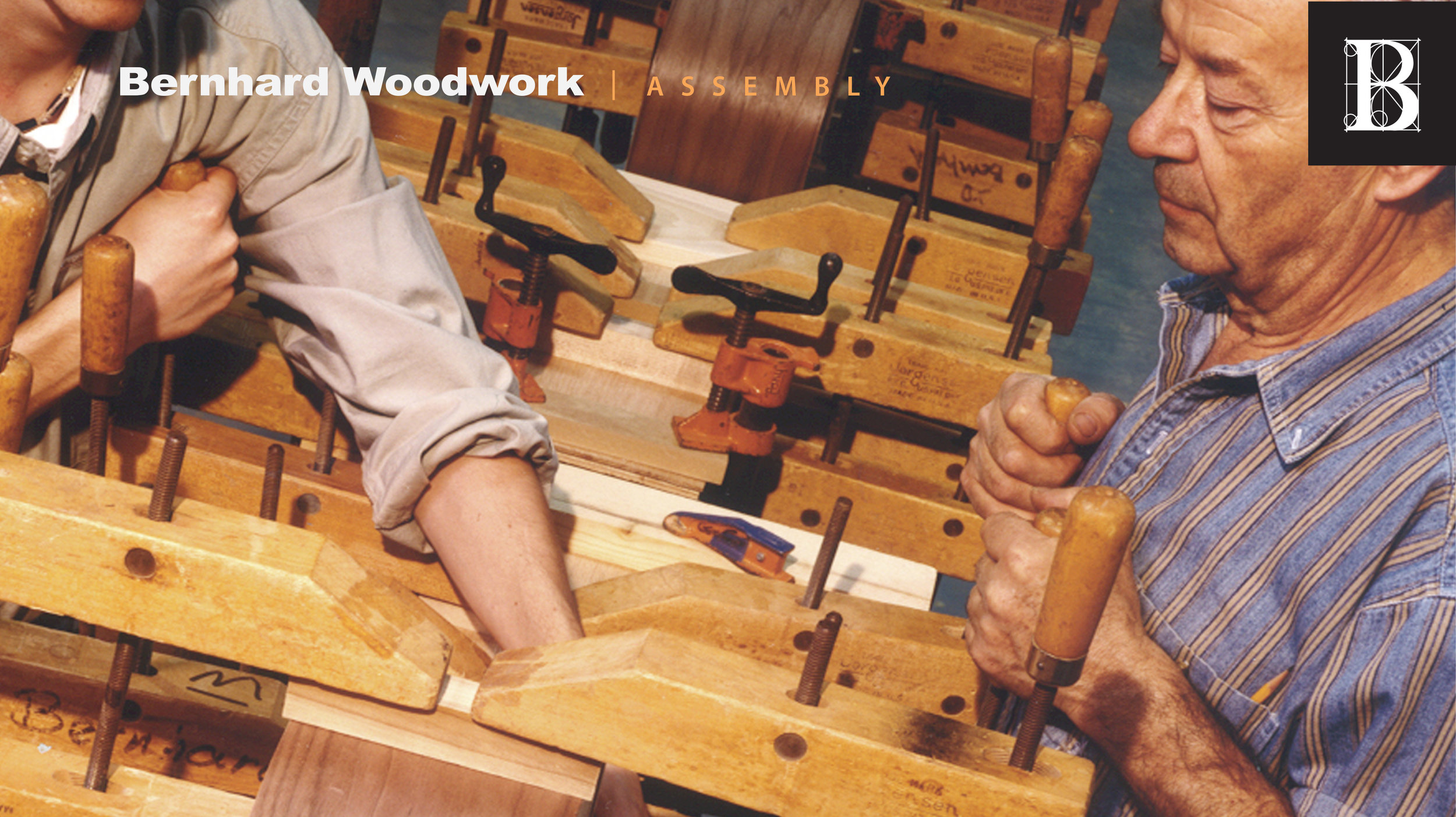

It’s in the assembly department that two-dimensional drawings come to life.

Machined panels and frames are joined, and piece assemblies are built from the ground up. After surface finishing, pieces return to assembly for installation of moldings and hardware such as drawer glides, hinges and pulls. Glass and trim are also fitted while electrical, telecom, data and other mechanical and access requirements are reviewed and accouned for. Only after the project manager and quality control supervisor have signed off on the last detail, the project is carefully packed for shipment to the client’s jobsite.

Our plant provides 100,000 square feet of fabricating, finishing, and administrative office space.

It is laid out and equipped for efficient integration of operations and material flow. A healthy, humidity-controlled environment reduces dust and maintains wood stability.