MACHINING

Our project manager will follow a job through from estimating to completion and billing. With an approved estimate, our draftsmen generate millwork drawings and a cut list (assisted by CAD/CAM systems that can translate drawings directly into CNC machine-code).

Every operation from sawing and laminating through joining, finishing and installation is accounted for.

Shop drawings, together with finished veneer and solid samples, are then submitted for customer sign-off. Before the first cuts are ever made, any aspects of design requiring special attention are identified and resolved.

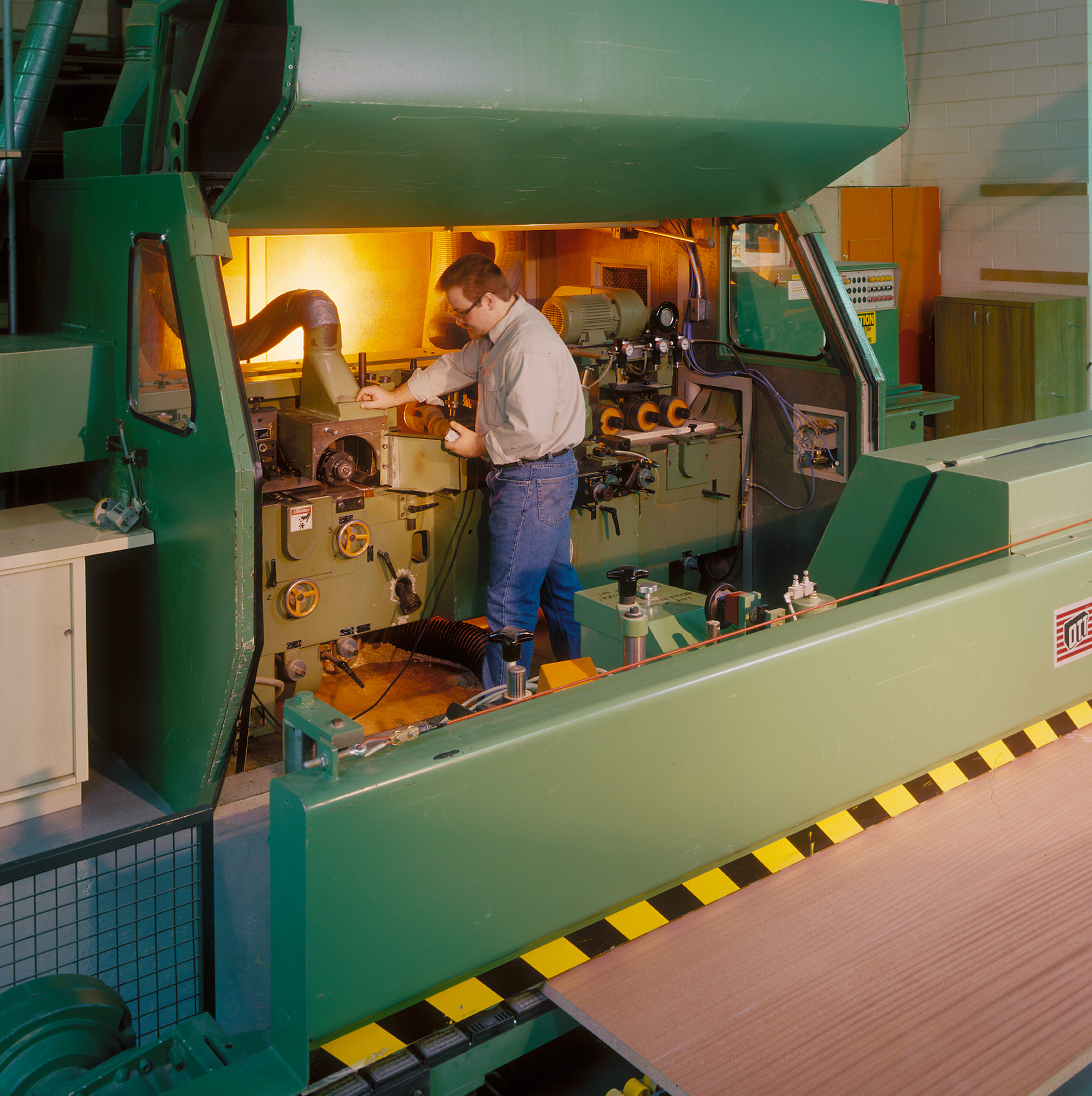

Our highly automated machining department with its many types of CNC equipped saws, joiners, routers and sanders is where a project begins to take on recognizable form. Other advanced equipment includes an edge-bander to laminate finished edges onto stock, and a V-groover, veneer edge-gluers and stitchers, automated planers and more.

The application of CNC routing to close-tolerance, complex or curved components makes production of highly creative installations more practical and economical.

Our Machining Department has over 600 molding dies. Pdfs of those molding profiles can be downloaded from this site in the Molding Profiles section.